In the swiftly progressing globe of electronics, printed motherboard (PCBs) play a vital function in making certain capability and integrity across a large range of devices. From microwave PCBs for communication systems to high-frequency PCBs in innovative applications, the demand for precise engineering and manufacturing processes has never been greater. Whether you're taking part in fast-turn custom PCB production or checking out the ins and outs of high-density interconnect (HDI) PCBs, understanding the nuances of PCB assembly and layout is vital for achieving optimal efficiency in your electronic tools.

Custom PCB manufacturing is an important aspect of modern electronics, permitting for tailored services that fulfill details functional requirements. Fast turn printed circuit board assembly is particularly valuable for industries that require quick growth cycles, such as telecoms and consumer electronics.

The need for HDI PCBs has actually surged, driven by the raising functionality of tools loaded right into smaller sized accounts. These boards utilize micro vias and advanced constructions to enable greater circuit density, essential for contemporary applications in mobile phones, wearables, and IoT gadgets. Manufacturers like those concentrating on Megtron 6 and Megtron 7 materials go to the leading edge of this modern technology, offering products that provide remarkable electrical efficiency and thermal administration. The integration of these materials right into the manufacturing process of circuit card assemblies drastically improves product dependability and efficiency, making them invaluable in a highly affordable landscape.

Flexible PCBs stand for another substantial innovation in innovation, enabling for bendable circuit styles that profit space-constrained applications. From flexible printed circuit board manufacturers to providers of RF PCBs, the industry has actually witnessed a change towards extra versatile remedies for modern electronics.

In the realm of RF circuits, cordless communication innovations have fueled the demand for specialized PCB styles, such as those using Rogers products. These materials are engineered to preserve signal integrity at high frequencies, making them the favored option for applications requiring minimal loss and high-performance features. Companies that can supply quick prototyping and assembly for RF PCBs are distinctly placed to offer the requirements of clients creating cutting-edge communication innovations.

The process of circuit board assembly involves numerous detailed actions, consisting of the positioning of parts, soldering, and testing. Each stage plays an important role in making certain that the end product meets quality standards and operational requirements. From low-volume PCB assembly for specialized applications to mass production of electronic motherboard, the capacity to manage every aspect of the PCB manufacturing assembly process is vital for companies looking for to boost their lower line while maintaining high requirements of top quality.

Improvements in PCB fabrication here methods, such as using blind and buried vias, have enabled designers to push the limitations of circuit density. Using these techniques not just enhances electrical efficiency however also enhances transmitting abilities, developing more portable and complex styles. This effectiveness is critical in today's electronics landscape, where space is at a premium, and gadget functionality proceeds to expand. Comprehending the dielectric residential or commercial properties of products such as FR-4 and other compounds is necessary for engineers aiming to make the most of performance.

For start-ups and recognized companies alike, the relevance of custom PCB assembly can't be overemphasized. By partnering with seasoned PCB manufacturers that comprehend the circuit board prototyping service nuances of PCB design and production, companies can make sure a shorter time-to-market, cost performance, and boosted item integrity.

The versatility of PCBs extends throughout a wide variety of applications, from industrial equipment to consumer electronics. Specialized circuit board styles provide to unique applications, with each segment calling for tailored services.

Trusted PCB manufacturing companies significantly focus on sustainable techniques in their operations. As ecological recognition grows, manufacturers are embracing greener approaches of PCB production and assembly, making use of lead-free solder and minimizing waste throughout fabrication. In addition, the impetus for better quality control protocols not just enhances consumer security yet additionally boosts compliance with worldwide requirements, guaranteeing customers of their product's integrity.

Making use of flexible circuit card is changing a number of industries as a result of their lightweight nature and capability to fit diverse type factors. The advancement of high-density interconnect PCBs has opened new methods in fields such as telecoms, where boosted data transfer abilities and lowered signal destruction website are vital. As modern technology advancements, the coexistence of rigid and flex PCBs makes it possible for designers to take advantage of the unique benefits of each while meeting rigorous performance criteria.

Innovation in PCB prototyping services simplifies the trajectory from conception to produce. Companies looking for PCB prototype suppliers that combine experience with advanced technology can accomplish substantial benefits during the item development phase. This fast-tracking of designs not just speeds up market access however also enables greater cutting-edge capacity as comments from prototype screening can drive subsequent style versions.

In the manufacturing landscape, the usage of sophisticated software program for PCB style and design makes sure precision in part placement and directing. Automation and AI-driven processes improve production line, making the production of detailed circuit assemblies extra effective. In addition, the surge of contract PCB assembly has made it possible for companies to concentrate on their core competencies while contracting out intricate PCB production jobs to specialized partners who significantly minimize overhead prices.

To conclude, the birth of the digital age has ushered in an era where printed motherboard act as the backbone of modern electronics. The constant evolution of PCB innovation-- from high-frequency microwave applications to flexible board manufacturing-- shows the huge potential for technology within this area. Companies that comprehend the ins and outs of PCB fabrication, style, and assembly can utilize these developments to develop products that are not only high-performing yet additionally dependable and economical. As sectors significantly demand quicker turnaround times and higher-quality requirements, the capacity to give options that deal with these demands will certainly define the next generation of electronic devices and systems. With a concentrate on bespoke manufacturing processes and innovative products, the future of printed motherboard is positioned for exciting advancements, forming the very material of innovation as we understand it.

Michael Fishman Then & Now!

Michael Fishman Then & Now! Burke Ramsey Then & Now!

Burke Ramsey Then & Now! Michelle Trachtenberg Then & Now!

Michelle Trachtenberg Then & Now! Earvin Johnson III Then & Now!

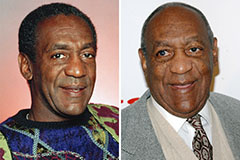

Earvin Johnson III Then & Now! Bill Cosby Then & Now!

Bill Cosby Then & Now!